Pulmodyne’s Indianapolis Headquarters expands with an additional 35,000 sq. ft. for manufacturing space.

- Pulmodyne and Alcove Manufacturing and Distribution announce partnership to innovate in drug atomization delivery.

Pulmodyne responds to the global Covid-19 pandemic by increasing filter output by nearly 10x.

- Launch of Pulmodyne DART and Reach; two high performance atomizing drug delivery devices.

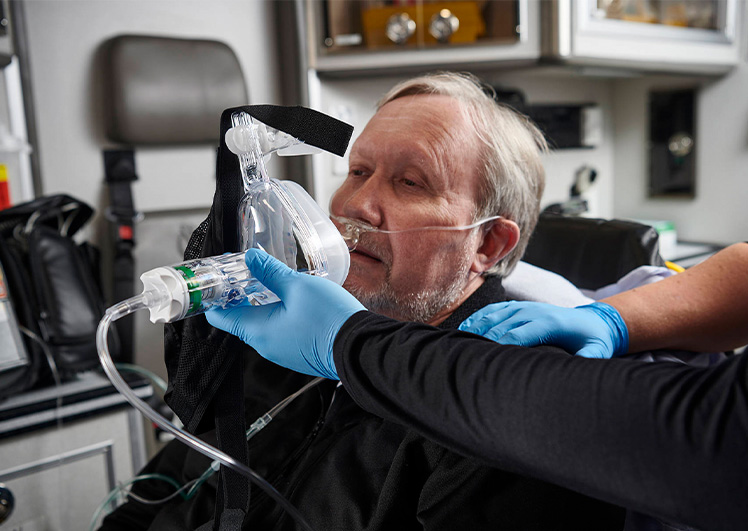

EMS acquires the distribution for Care2 Innovation products. The portfolio includes technology in stabilization and nebulization.

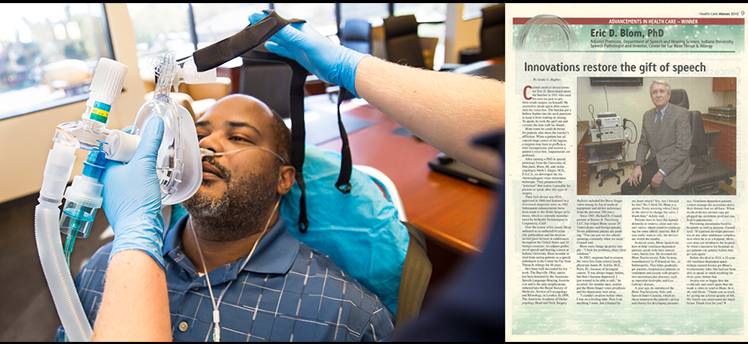

- Launch of the Naso-Flo II – The first nasopharyngeal tube system with integrated capnography.

Opening of EMS’s second factory in Penang, Malaysia.

- Launch of the Pediatric Maxshield, the first pediatric NIV mask offered by Pulmodyne.

- Launch of Pulmodyne’s newest line of ventilator HME/Filters.

Launch of the Go-PAP Disposable CPAP System. This is the first low flow system launched by Pulmodyne.

Launch of the Control-Cric® Cricothyrotomy System. Designed with Dr. Rich Levitan, it has become the gold standard for emergency cricothyrotomy.

Engineered Medical Systems-Malaysia opens.

Launch of the AccuPAP® device for post-operative atelectasis.

- Launch of the O2-MAX® Trio, allowing for multiple levels of oxygen delivery within a single, disposable CPAP kit.

Launch of the O2-MAX®. The O2-MAX® innovated to change FiO2 and PEEP options.

Launch of the O2-MAX®. This the first, fully disposable, high pressure CPAP system. Today, it is the world leader in disposable CPAP.

- Launch of the O2-RESQ. This is the first fully disposable, high-pressure CPAP system for the treatment of congestive heart failure.

Launched the brand “Pulmodyne” as their in-house brand of products. Further, it allowed the company to build products, and grow them for the long term.

- Launch of the BiTrac® NIV Mask line. This is a complete line of disposable,non-invasive ventilator masks that is currently sold in 50 countries.

Expansion of the CobraPLA Supraglottic Airway product to addCobraPLUS

Launch of the CobraPLASupraglottic Airway

EMS purchased and remodeled the Indianapolis facility with 41,000 sq/ft on 5 acres, with the ability to expand an additional 35,000 sq/ft.

EMS starts producing 3K resuscitator bag per month for a major US medical company. From there, they attracted and built products for additional OEM customers.

EMS leases a 2700 sq/ft. space. From there, they built tooling to produce cones and cushions for the CPAP mask. They hired their first employee at this time.

After years of experience in automotive part manufacturing, Jeff & Brad Quinn are approached by a firm looking for a face mask. Later that year, Engineered Medical Systems (EMS) was founded, and the company began making Homecare CPAP Masks for Puritan Bennet OSA Machines. This began on a tabletop in a 200 sq/ft room. At night, Brad and Jeff would glue masks by hand, and cure them in a $300 tanning bed.

World Wide Distribution

Pulmodyne products are sold exclusively by distribution partners in defined geographic areas worldwide.To inquire about the products we offer, locate a distributor in your area, or for inquiries about areas available for distribution, please contact the appropriate sales manager below for your geographical area.

National Distribution Emergency & PreHospital

Products like the O2-MAX®, GO-PAP, and the Control-Cric® are available through the distributors

ContactNational Distribution

Acute Care

Products like the BiTrac® NIV, O2-MAX®, GO-PAP, and the Control-Cric® are available through the distributors

ContactInternational

Distribution

Products like the BiTrac® NIV, O2-MAX®, and the GO-PAP are available through International markets. Contact our International Sales Manager to find a distributor in your country.

Contact